As we move into 2025, the welding industry is experiencing significant changes. Rapid technological advancements, the growing demand for skilled workers, and an evolving focus on precision and safety drive these shifts. In such a dynamic environment, employers are increasingly looking for welders who possess not just technical expertise but also a wide array of essential skills. Whether you’re aiming for commercial welding jobs or advancing your welding career, understanding what employers expect in 2025 can give you a significant edge.

The welding sector has traditionally been associated with manual labor, but as the industry grows and adapts, the expectations for welders are shifting. Today’s employers seek professionals who are well-versed in modern welding techniques, understand complex blueprints, can work with state-of-the-art equipment, and can collaborate efficiently in team settings.

In this article, we will explore the essential skills that are shaping welding jobs in 2025 and beyond. We will delve into the technical abilities that welders must master, as well as the soft skills that will help them stand out in an increasingly competitive market. By the end of this article, you’ll understand how to position yourself as a top candidate for welding jobs, whether you’re seeking commercial welding jobs or planning a long-term career in welding.

1. The Growing Demand for Skilled Welders in 2025

Welding has long been essential in industries like construction, automotive manufacturing, and infrastructure development. Recently, the demand for skilled welders has surged and is expected to keep growing in 2025 and beyond.

Industry reports predict significant growth due to increased construction, renewable energy projects, and advancements in automation and robotics. Welders play a crucial role in building infrastructure, especially in commercial welding jobs that require precision and expertise.

Welders are also highly demanded in emerging sectors like sustainable energy, including the wind turbine, solar, and electric vehicle industries. As companies work toward sustainability goals, welding jobs in these fields are expected to rise.

For those pursuing welding careers, 2025 offers exciting opportunities. Leveraging a mix of technical and soft skills will be key to success, whether you’re just starting or established in the field.

2. Essential Technical Skills for Welders

Welders must possess a diverse skill set to meet the technical demands of welding jobs. For those pursuing welding careers, here are some of the most important technical skills employers will expect welders to demonstrate in 2025.

Welding Techniques

One of the core aspects of being a welder is mastering different welding techniques. There are several methods, and employers expect welders to be skilled in more than one of them. The key welding techniques that will be in demand include:

- MIG Welding (Metal Inert Gas): This technique is one of the most widely used in the industry, particularly in construction and manufacturing. It is a versatile method that involves feeding a wire through a welding gun to create a stable, high-quality weld. MIG welding is especially important for commercial welding jobs as it is fast and efficient, making it ideal for large-scale production.

- TIG Welding (Tungsten Inert Gas): Known for its precision, TIG welding is often used for more intricate projects that require a clean, smooth finish. This method is common in industries such as aerospace and automotive, and welders in these fields must be highly skilled in it.

- Stick Welding (SMAW): While it is an older technique, Stick welding remains valuable due to its versatility and ability to weld thick materials in various environments. It’s still a critical skill for many commercial and industrial welding applications.

- Flux-Cored Arc Welding (FCAW): This is an advanced form of MIG welding used in heavy industries like shipbuilding and steel construction. It is highly effective for welding thick metals and is important for welders aiming to work in commercial welding jobs and other industrial settings.

Blueprint Reading

In 2025, welding is no longer just about following instructions or “winging it.” Welders need to be able to read and interpret blueprints, technical drawings, and schematics with precision. Blueprint reading is essential for ensuring that welds are made according to specific measurements, angles, and tolerances. It also ensures that materials are welded correctly, avoiding costly errors and ensuring safety.

For individuals pursuing welding careers, being proficient in blueprint reading is crucial. Employers expect welders to have a solid understanding of the symbols used in technical drawings, as well as the ability to calculate dimensions and assess the scope of the welding project. Whether you’re working on commercial welding jobs or a specialized project, the ability to read blueprints is a fundamental skill.

Welding Safety

Safety has always been a priority in the welding industry, and it will continue to be a top concern in 2025. Modern welding jobs require a keen understanding of safety protocols to prevent injuries, accidents, and long-term health issues.

Welders must be aware of safety standards such as:

- Personal Protective Equipment (PPE): Wear the right gear (helmets, gloves, safety goggles, etc.) to protect against burns, sparks, and other welding hazards.

- Ventilation and Fume Control: Understanding the risks associated with fumes and how to implement proper ventilation and extraction systems.

- Equipment Safety: Welding equipment must be well-maintained and operating safely to prevent malfunctions or hazards. Employers in 2025 will prioritize safety-conscious welders who not only follow safety procedures but are proactive in identifying and mitigating potential risks on the job. Maintaining a high standard of safety will be a key component to long-term success for those looking to grow in the field.

Welding Equipment

Welding tools are evolving rapidly, and welders must be adept at handling the latest equipment. New welding machines and automated systems are becoming more common, especially in commercial welding jobs. Experience with advanced tools like automated welding robots, CNC machines, and digital controls will be a significant asset.

In addition to these advanced tools, welders must also be familiar with more traditional equipment, such as plasma cutters, grinders, and welding torches, depending on the specific needs of the job. As technology advances, staying up-to-date with the latest equipment will be vital for anyone looking to advance in their welding careers.

3. Soft Skills Employers Value in Welders

While technical expertise is essential, employers in 2025 will also expect welders to possess strong soft skills. Here are some key non-technical abilities that will set welders apart in the job market, especially for those looking to advance in the field.

- Attention to Detail

Welding requires precision, and even a small mistake can result in poor-quality or unsafe welds. Employers value meticulous welders who deliver work that meets industry standards. Attention to detail ensures strong, visually appealing, and defect-free welds, which is crucial for those pursuing welding careers in high-precision industries. - Problem-Solving

Welding is not a one-size-fits-all job. Welders often face unique challenges, such as working with difficult materials, overcoming unexpected obstacles, or finding solutions to unexpected issues during a job. Employers expect welders to be problem-solvers who can think on their feet and find solutions to complex issues, ensuring the job gets done right. These problem-solving skills will help welders in welding careers tackle difficult projects efficiently and effectively. - Teamwork

While welding is often considered a solitary task, most welders work as part of a team. Whether collaborating with engineers, project managers, or other tradespeople, effective communication and teamwork are essential for success. Employers want welders who can work well with others and contribute to a positive and efficient work environment. Being a good team player will help you advance in your welding career and increase your value to employers. - Communication

Good communication skills are vital in welding jobs. Welders must be able to communicate their needs, challenges, and progress to supervisors, clients, and team members. Clear communication ensures that the project moves forward without delays and that any concerns are addressed in a timely manner. Strong communication will make you stand out in your welding career, particularly in collaborative or high-stakes environments.

4. Technological Advancements and the Future of Welding Jobs

The welding industry is not immune to the effects of automation and digitalization. In fact, advancements in technology are transforming the landscape of welding jobs, especially in commercial settings.

Robotics and Automation

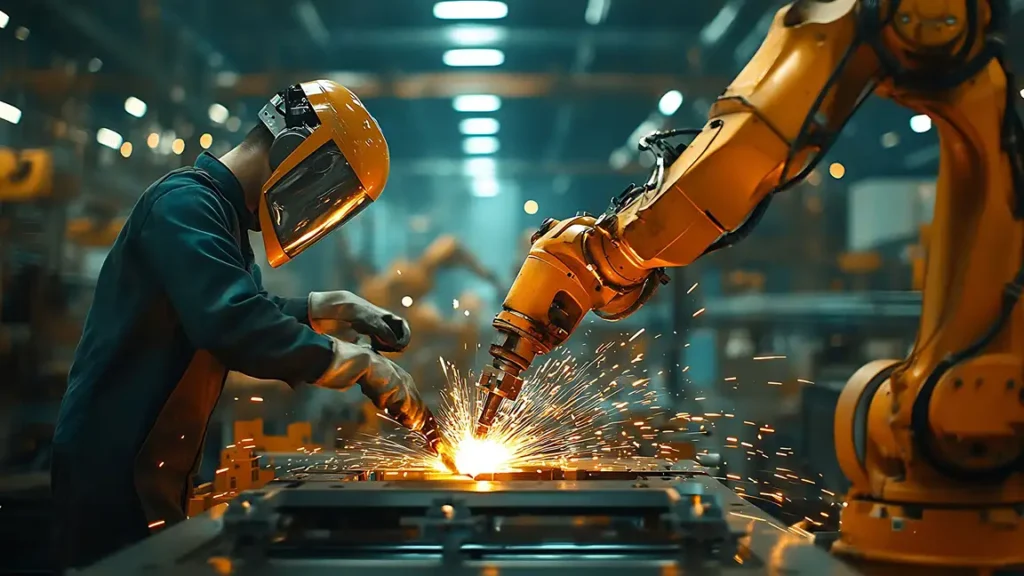

Robotic welding systems have become increasingly common in industries that require high production rates, such as automotive and manufacturing. Welders must be comfortable working alongside robotic systems, adjusting parameters, and ensuring the machines are operating correctly.

While robots perform many tasks, human welders are still essential for overseeing the process, troubleshooting, and ensuring quality. Understanding how to work with robots and automated systems will be a significant asset for welders in 2025, especially for those pursuing welding careers in high-tech industries.

AI and Machine Learning

The integration of artificial intelligence (AI) in welding equipment is also on the rise. Smart welding machines that learn from previous jobs and adapt to different conditions are becoming more prevalent. Welders who understand how to leverage these technologies will be in high demand, as they can help streamline the welding process and improve the overall quality of the work. Staying ahead of AI advancements will be a key factor in future success for those looking to grow in their welding careers.

5. Certification and Training: Key to Success in Welding Careers

In 2025, formal certification will remain one of the most important factors for welders seeking to advance their careers. Certifications from the American Welding Society (AWS) or the American Society of Mechanical Engineers (ASME) provide credibility and demonstrate that a welder has the required skills and knowledge to handle complex jobs.

In addition to certifications, ongoing training and professional development will be essential. The welding industry is rapidly evolving, and welders must stay current with the latest techniques, tools, and safety standards to remain competitive. Welding apprenticeships, online courses, and trade schools all offer opportunities for welders to continue learning and improving their skills.

6. Understanding Industry-Specific Requirements for Welding Jobs

Different industries have different requirements for welding jobs. For example, welders working in aerospace may be required to use specialized materials and techniques that are not necessary in general construction. Similarly, welders in the energy sector may need to work with extremely high pressures or temperatures.

Tailoring your skills to the specific requirements of the industry you’re interested in can give you a distinct advantage when applying for commercial welding jobs. Understanding the nuances of each sector and the specialized skills required will help you position yourself as a sought-after candidate in welding careers.

7. How to Stand Out as a Welder in 2025

To succeed in welding careers, it’s important to differentiate yourself from the competition. Here are a few strategies to enhance your welding profile:

- Build a Strong Portfolio: Create a portfolio showcasing your skills, projects, certifications, and awards. A well-organized portfolio highlights your professionalism and helps employers assess your expertise, particularly when applying for commercial welding jobs where quality and consistency are key.

- Network Actively: Attend welding conferences and workshops and join professional associations to connect with others in the industry. Networking opens doors to job opportunities and collaborations and keeps you informed about industry trends. Connecting with professionals in commercial welding jobs can also help you learn about new opportunities in the field.

- Stay Updated with Industry Trends and Technologies. Continuously learn about new welding techniques, tools, and automation advancements. Being knowledgeable about the latest technologies makes you more valuable to employers who need welders skilled in cutting-edge methods. Staying ahead of technological trends is essential to remaining competitive in the field.

- Seek Specialized Certifications and Training: Earn certifications from respected organizations like the American Welding Society (AWS). Specializing in high-demand areas, such as aerospace or renewable energy welding, can make you more marketable. These certifications are particularly valuable when aiming for commercial welding jobs, where advanced skills are often required.

- Showcase Soft Skills and Leadership: Employers value soft skills like teamwork, communication, and problem-solving . Taking on leadership roles or mentoring others shows you can collaborate and manage projects effectively.These traits are especially important in commercial welding jobs, where you may work with diverse teams on large-scale projects.

Conclusion

The welding industry in 2025 presents exciting opportunities for those with the right skills and mindset. By mastering essential technical skills, staying up-to-date with industry trends, and honing soft skills, welders can position themselves for success in this fast-paced, high-demand field. Whether you’re starting out or looking to advance in welding jobs, investing in training and adapting to new technologies will ensure you’re prepared for the future of welding.