Industrial engineering jobs play a critical role in shaping industries worldwide by optimizing systems, processes, and resources. As businesses and manufacturing practices evolve, so does the scope of these roles. With the advent of new technologies like automation, data analytics, and IoT, industrial engineers are stepping into new roles and embracing digital tools that were once unimaginable.

Over the past decade, we’ve witnessed a radical transformation in how industries operate, and as these technologies continue to advance, the demand for skilled engineers will only increase. Today’s industrial engineers must embrace an interdisciplinary skill set and prepare to adapt to changes that will redefine entire sectors of manufacturing, industrial design jobs, and industrial maintenance jobs. This article explores the emerging trends and technologies that are reshaping industrial engineering roles, including those in design and maintenance. It highlights the shifts in skill sets, job functions, and the exciting opportunities that lie ahead for professionals in this field.

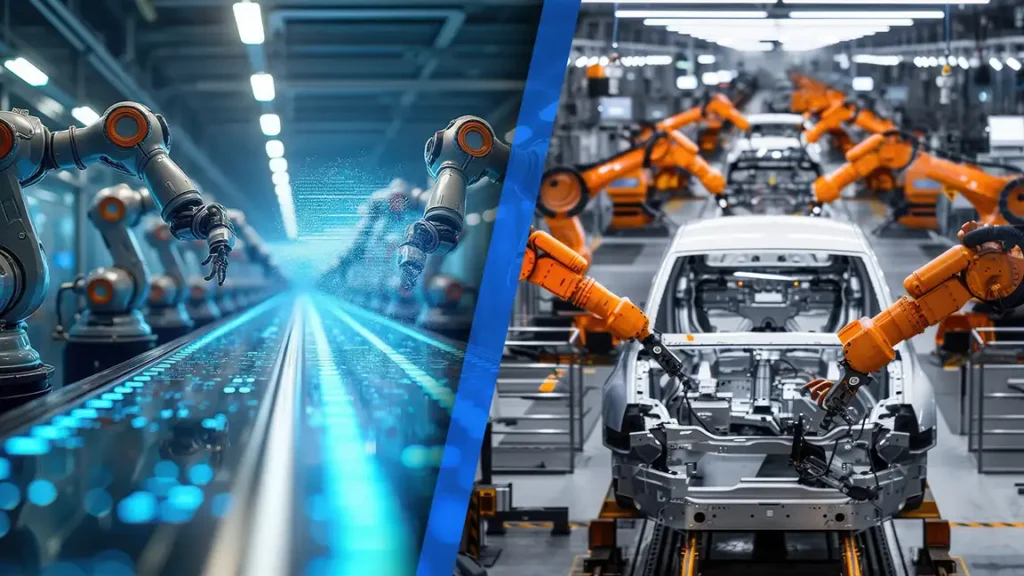

1. The Rise of Automation and Artificial Intelligence in Industrial Engineering

Automation has been a cornerstone of modern industrial engineering jobs for decades. The implementation of automated machinery, such as conveyor belts, robotic arms, and 3D printers, has significantly increased productivity in manufacturing settings. Today, automation continues to progress, incorporating Artificial Intelligence (AI) and machine learning to create smarter, self-learning systems that can adapt to changing conditions.

A New Era of Automation

The integration of automation and AI is revolutionizing industrial engineering jobs by enabling smarter factories and robotics across various industries. Industrial engineers are now tasked with designing and managing AI-powered systems to optimize production, reduce waste, and predict equipment failures. This trend, seen in companies like Tesla, is driving demand for engineers who can incorporate these technologies into existing systems. At the same time, industrial design jobs are evolving to include AI and automation, resulting in more efficient, cost-effective designs. Additionally, industrial maintenance jobs will be essential to ensure the continued performance and reliability of these advanced systems.

Impact on Industrial Maintenance Jobs

As automation and AI continue to take over repetitive tasks, industrial maintenance jobs will evolve to oversee and maintain these advanced systems. The responsibilities of industrial maintenance engineers will extend beyond traditional mechanical maintenance to include data-driven diagnostics, remote monitoring, and troubleshooting of AI-powered systems. The rise of predictive maintenance technology will allow engineers to intervene proactively, ensuring that automated systems remain operational without interrupting the production process.

While automation may replace some manual tasks, industrial engineering jobs will remain highly demanded to manage and maintain these sophisticated systems. Engineers’ key to success will be their ability to work with automation systems and understand the intricacies of the machine learning algorithms that power these technologies. By embracing these advancements, industrial engineers will be at the forefront of a new era in manufacturing and maintenance. Additionally, industrial design jobs will also benefit from these innovations, as automation and AI enable more efficient and precise product development.

2. The Role of Data Analytics in Shaping Industrial Engineering Careers

Data analytics has become a transformative force in industrial engineering jobs. With the increased reliance on sensors, IoT devices, and advanced data collection methods, industries are generating vast amounts of data. However, collecting this data is only part of the equation; industrial engineers must now focus on analyzing and interpreting this data to optimize systems, reduce inefficiencies, and predict future trends.

Big Data and Industrial Engineering

Big data analytics is transforming industrial engineering jobs by enabling engineers to make data-driven decisions that improve efficiency and performance. By analyzing real-time data from production processes, engineers can identify bottlenecks, predict equipment failures, and optimize supply chains. This proactive approach enhances productivity and reduces costs. The rise of big data has also led to new roles in industrial engineering jobs, requiring expertise in statistics, machine learning, and programming languages like Python, R, and SQL. These advancements allow engineers to refine systems and drive innovation across industries. Additionally, industrial design jobs are also evolving as data analytics informs the design process, helping engineers create more efficient, cost-effective, and sustainable products.

Industrial Design Jobs and Data

The integration of data analytics into industrial design jobs is transforming the design process. Engineers now use vast datasets to optimize designs, select materials, predict failures, and streamline production. For example, General Electric uses real-time data from gas turbines to improve designs and performance, resulting in more efficient and cost-effective products. This data-driven approach has shortened development timelines, reduced prototyping costs, and improved design accuracy. In industrial engineering jobs, the ability to quickly iterate using data and advanced simulation tools allows for better-informed decisions that meet safety and performance standards.

Industrial Maintenance Jobs and Data

Data analytics is transforming industrial maintenance jobs by enabling engineers to predict equipment failures and schedule proactive repairs, minimizing downtime and costs. By using real-time data from sensors, maintenance processes are shifting from reactive to predictive, improving overall efficiency. As this trend continues, workers in industrial maintenance jobs must develop strong analytical skills and an understanding of machine learning to interpret sensor data. Additionally, industrial engineering jobs and industrial design jobs are benefiting from data analytics, with engineers optimizing production and design processes to improve maintenance and system reliability.

3. Sustainable Practices and Green Engineering: Shaping Future Job Roles

Sustainability has moved to the forefront of industrial engineering as environmental concerns continue to grow. Companies are increasingly being held accountable for their environmental footprint, and industrial engineers are key players in helping them achieve sustainability goals. From reducing energy consumption to cutting down on waste, the focus on sustainable engineering practices is creating new roles and job opportunities for industrial engineers.

Sustainable Manufacturing and Industrial Engineering

Industrial engineers are driving sustainable manufacturing by implementing practices that reduce waste, energy usage, and environmental impact. Lean manufacturing principles are being used to minimize raw material waste, while renewable energy sources like solar and wind power are being incorporated into production processes. A growing area in industrial engineering jobs is green engineering, where engineers focus on energy efficiency, renewable energy, and waste management. Additionally, there is a rising demand for industrial design jobs centered on sustainable product design, eco-friendly materials, and circular economy principles. Industrial maintenance jobs are also benefiting from these advancements, as maintenance engineers work to optimize energy use and improve the sustainability of production systems.

Industrial Maintenance and Sustainability

In the realm of industrial maintenance, sustainability is driving new approaches. Maintenance engineers are tasked with implementing and maintaining systems that help reduce energy consumption and extend the lifespan of equipment. Regular maintenance of renewable energy systems, such as solar panels or wind turbines, will become a major focus area for engineers, offering new career paths in these sectors. As industries shift toward greener practices, engineers who specialize in environmental sustainability will find themselves in high demand. Specialized knowledge of sustainable energy, waste management systems, and eco-friendly design will become increasingly valuable in the future job market, particularly in industrial engineering jobs and industrial design jobs.

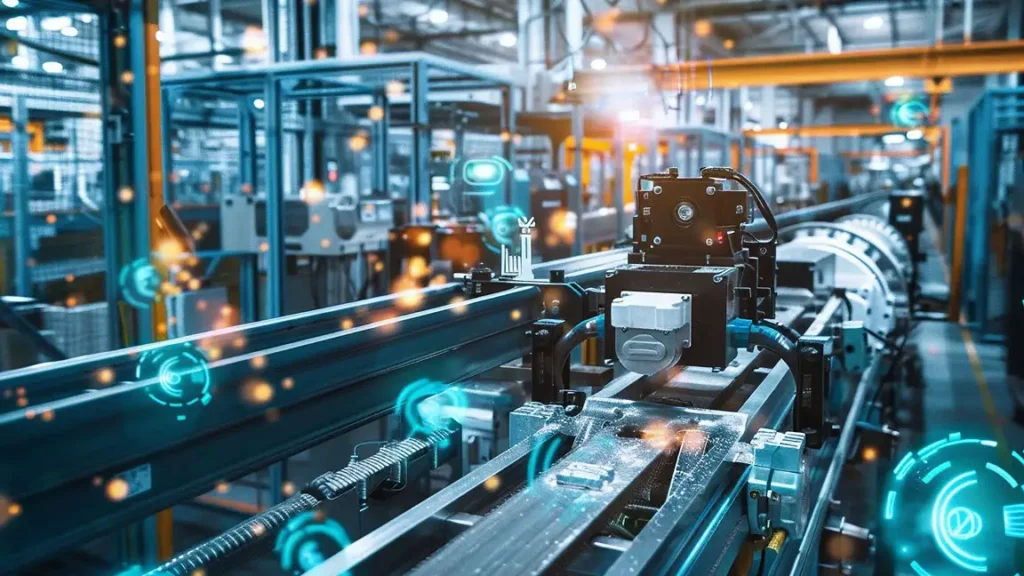

4. The Internet of Things (IoT) and the Connected Factory

The Internet of Things (IoT) has emerged as a transformative technology across many industries, particularly manufacturing. By connecting machines, sensors, and devices through the Internet, IoT allows for real-time data collection and monitoring. This connectivity enables engineers to track performance, diagnose issues, and optimize operations in previously unimaginable ways.

Connected Factories and Smart Manufacturing

The concept of the smart factory is gaining traction as more manufacturers integrate IoT devices into their production lines. Sensors embedded in machines monitor every aspect of the production process, from temperature and pressure to vibrations and wear. This data is then fed into cloud-based platforms, allowing engineers to monitor systems remotely, identify inefficiencies, and predict when a machine will need maintenance.

Impact on Industrial Maintenance Jobs

Industrial maintenance jobs are transforming in IoT-enabled factories. Remote monitoring of machines allows maintenance engineers to diagnose issues before they become critical, leading to less downtime and fewer costly repairs. Predictive maintenance, powered by IoT sensors, uses data to forecast when a machine will fail, enabling engineers to replace parts or make adjustments before a breakdown occurs.

Industrial Design Jobs and IoT

As IoT technology advances, industrial design jobs are evolving as well. Engineers are increasingly designing products with IoT capabilities built in. These smart devices provide real-time data, which can be used for everything from remote control to predictive analysis of product performance. For example, industrial designers in the consumer electronics sector are integrating IoT features into products to make them smarter and more connected.

The industrial designer’s role is shifting from traditional product development to incorporating connectivity and data-driven features into new products. Engineers will need to be skilled at designing devices that are compatible with IoT systems, ensuring smooth communication between machines, sensors, and cloud-based software.

5. The Shift Towards Digital Twins and Simulation Technologies

Digital twins—virtual replicas of physical objects or systems—are revolutionizing industrial engineering jobs by enabling engineers to simulate real-world conditions and predict system behavior. The concept of a digital twin involves creating a virtual model of a physical system, such as a production line, a piece of machinery, or even an entire factory.

What Are Digital Twins and How Do They Work?

A digital twin is a real-time, digital replica of a physical asset, process, or system that is used for simulation and analysis. Using sensors and IoT technologies, the physical object sends data to the digital twin, allowing engineers to monitor performance, detect problems, and even test out new configurations before making changes to the physical system.

For example, a digital twin of an industrial plant can be used to simulate different operational conditions, helping engineers optimize equipment performance and reduce downtime. This predictive modeling technology offers a better understanding of how systems behave under various conditions, leading to more efficient designs and maintenance schedules. As a result, industrial engineering jobs are evolving to incorporate digital twin technology, creating new opportunities for engineers to improve system efficiency and reduce costs through advanced simulations and predictive analysis. In the context of industrial design jobs, digital twins enable designers to test and improve designs virtually, saving time and resources before moving to physical production. Furthermore, industrial maintenance jobs benefit from digital twins by enabling predictive maintenance, allowing engineers to anticipate and address potential equipment failures before they occur, thereby minimizing costly downtime.

Impact on Industrial Engineering Jobs

The rise of digital twins presents exciting opportunities for industrial engineering jobs, particularly in areas like simulation, modeling, and optimization. Engineers will need to develop expertise in simulation software, machine learning, and virtual modeling to design and maintain these complex systems. As digital twins enable real-time monitoring and analysis, industrial engineers will have more tools to enhance efficiency, minimize disruptions, and anticipate potential issues before they arise.

With industries increasingly relying on digital twin technology, industrial engineers will be highly demanded to implement, manage, and optimize these systems. Whether monitoring a factory’s production line or improving a product design, digital twins are reshaping engineers’ roles and responsibilities. In industrial maintenance jobs, digital twins will also play a critical role in predictive maintenance, allowing engineers to anticipate failures and optimize repair schedules to minimize downtime and improve asset longevity.

Industrial Design Jobs and Digital Twins

Industrial design jobs are being transformed by digital twin technology, allowing designers to test and refine designs before physical production. This accelerates development, reduces prototyping costs, and helps identify issues early. In industries like aerospace and automotive, digital twins enable designers to simulate configurations and ensure products meet performance, safety, and efficiency standards. This iterative process leads to more precise, optimized designs, improving quality and reducing time-to-market.

Industrial Maintenance Jobs and Digital Twins

Industrial maintenance jobs are being revolutionized by digital twins, which provide real-time data to monitor machinery health and predict potential failures. This predictive maintenance strategy allows maintenance teams to schedule repairs proactively, reduce downtime, and extend equipment lifespan. By analyzing data from digital twins, engineers can foresee issues before they occur, enabling timely maintenance and reducing costs related to unplanned breakdowns.

6. Skills and Education for the Future of Industrial Engineering Jobs

As industrial engineering continues to evolve, so must the skills of its professionals. The rise of automation, AI, data analytics, and IoT is creating a new set of expectations for industrial engineers. While technical skills in process optimization and systems design will continue to be important, engineers must now possess an interdisciplinary skillset to remain competitive.

Developing New Skills for Emerging Technologies

Engineers will need to be proficient in data science, machine learning, AI programming, and IoT technologies. The ability to analyze data, develop predictive models, and implement advanced automation systems will become essential in the modern industrial engineering role. Additionally, soft skills such as communication, problem-solving, and adaptability will be crucial as engineers work alongside professionals from other disciplines.

7. Challenges and Opportunities in the Future Industrial Engineering Job Market

As automation and AI take center stage, there are concerns about job displacement, particularly in traditional roles. However, many experts believe that automation will create new types of jobs rather than eliminate existing ones. Engineers who can adapt to new technologies will be better equipped to thrive in the changing landscape of industrial engineering.

Conclusion

The future of industrial engineering jobs and industrial maintenance jobs is promising, with technologies like automation, AI, IoT, and data analytics transforming industries. As demand for skilled professionals in these fields grows, continuous learning, adaptability, and embracing new technologies will be key to success. By staying at the forefront of innovation, industrial engineers and maintenance professionals will continue to play a crucial role in shaping the future of manufacturing and beyond, with expanding opportunities to contribute across various industries. Additionally, industrial design jobs will also evolve as these technological advancements create new possibilities for more efficient and sustainable product development.